WAVE ELEMENTS

Digital Ceramics - Clay 3D Printing

Linshen Xie, Jisoo Sim

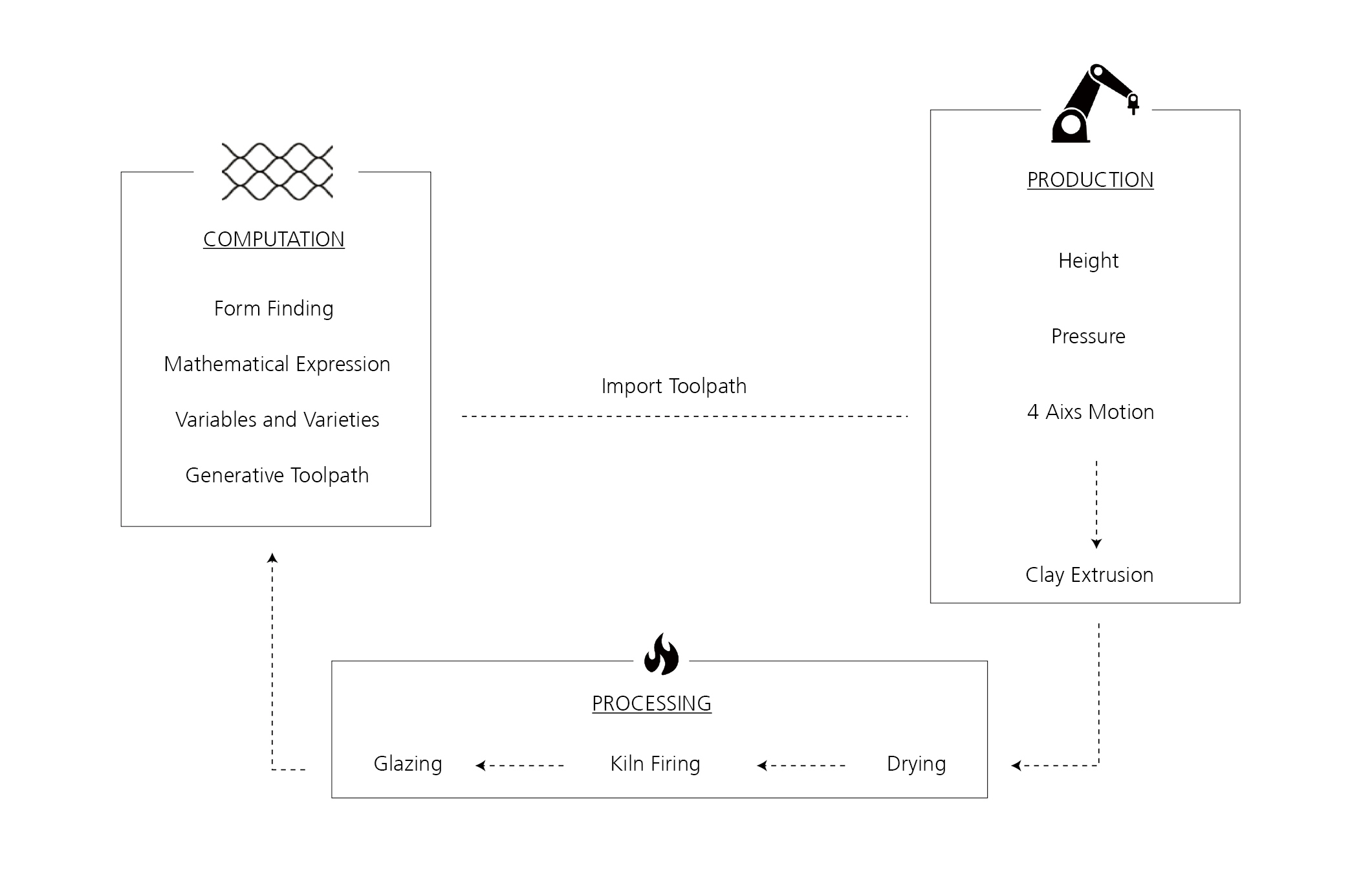

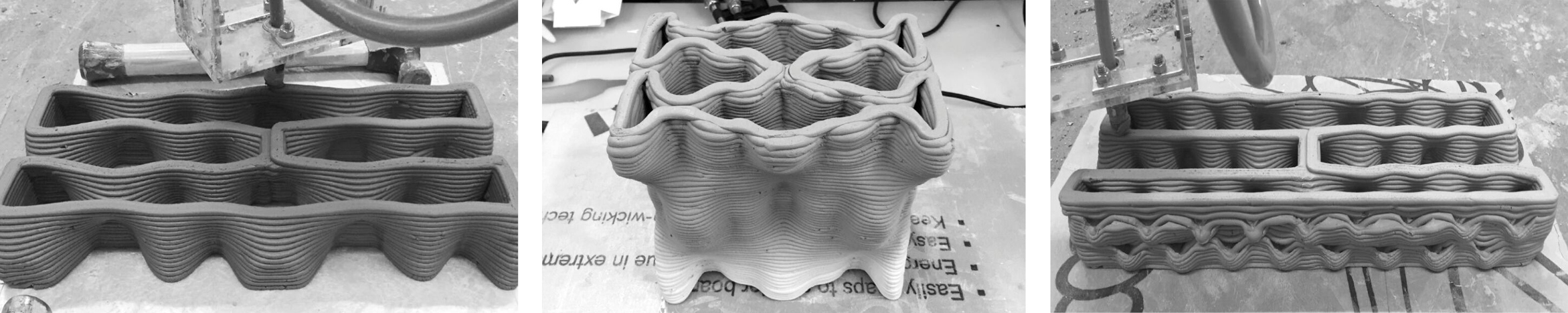

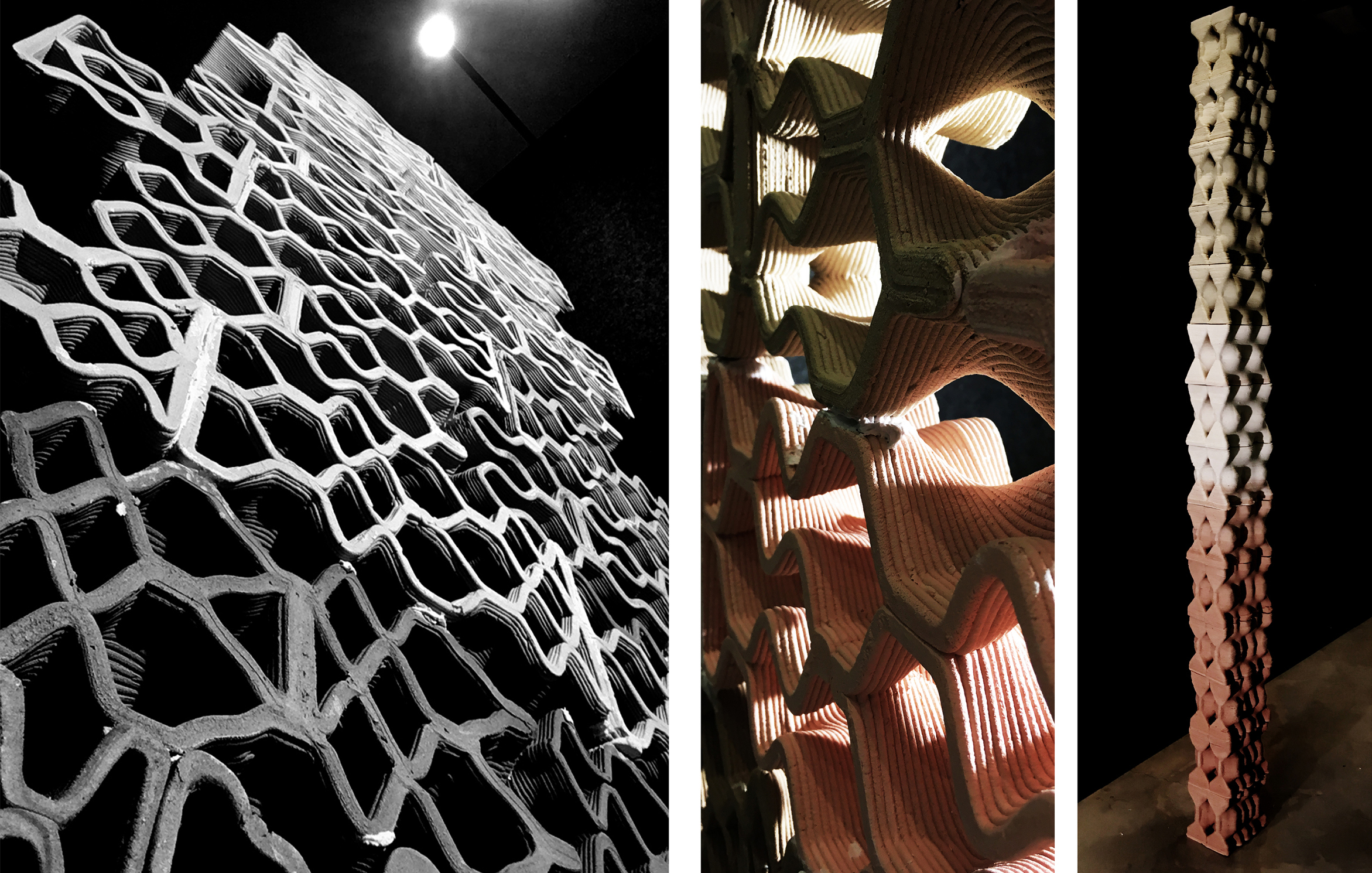

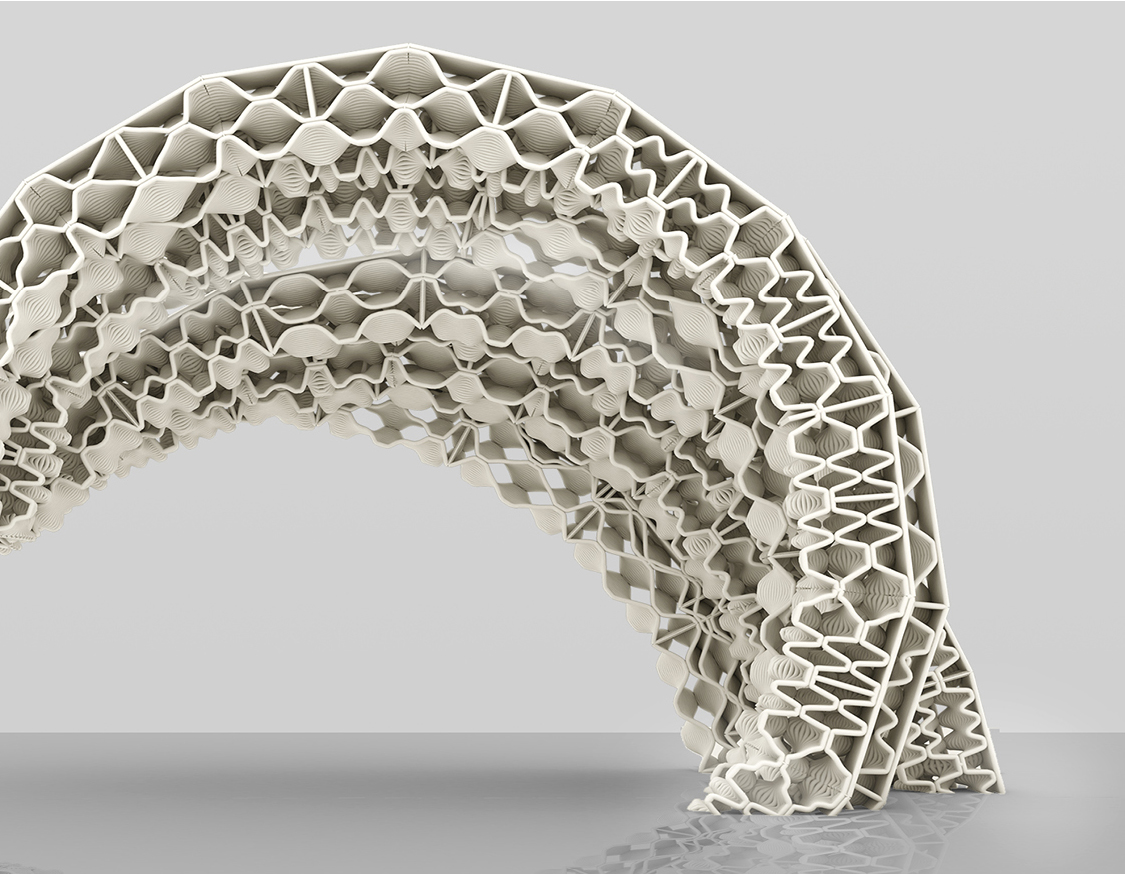

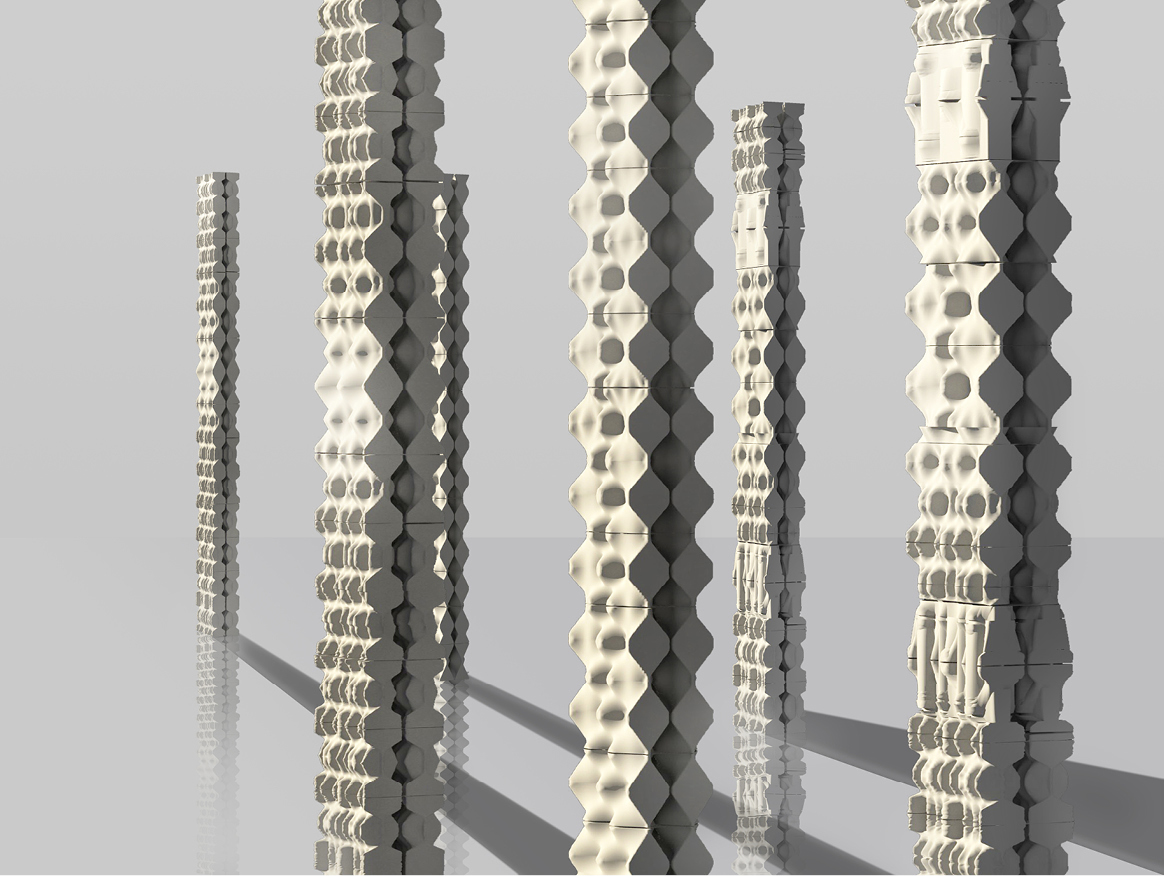

Wave Element is the melding of computational form generation with an experimentation of the capabilities of automated robotic 3D printing of clay to explore ceramic as a feasible architectural material. The design analyzes a series of base curves, the transformation of which serves as a generative logic in the form of a unit expressed in the global, local, and micro scale. Incorporation of different calibration techniques native to the function of the robot and the manipulation of ceramic material aims to add another layer of information, embedding an element of the extrusion and printing process into the resulting form. The robot arm performs a pivotal role in specifically customizing every piece, redefining the mass production of modular building materials. We aim to explore the structural possibilities of a ceramic modular unit by adapting it to different structural forms such as that of a wall, column, and arch.

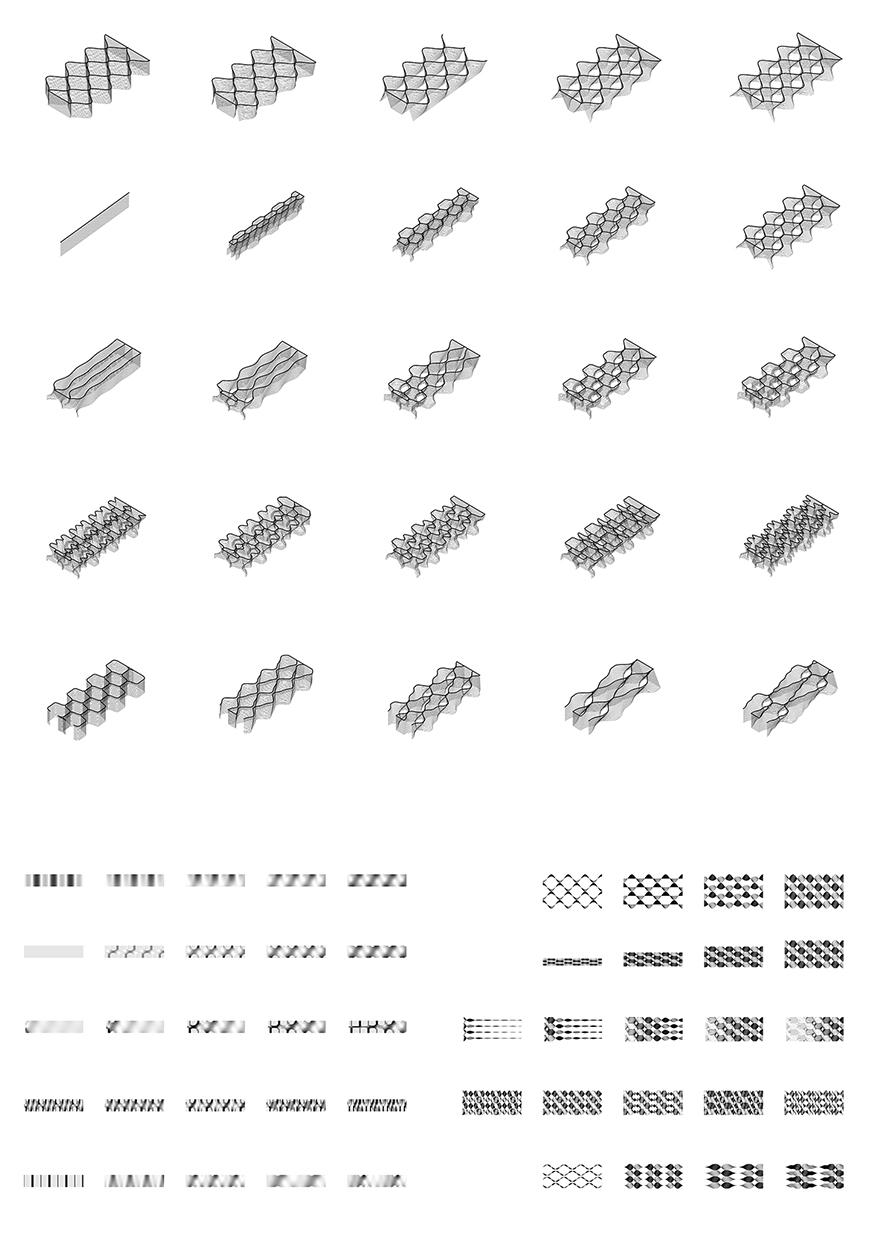

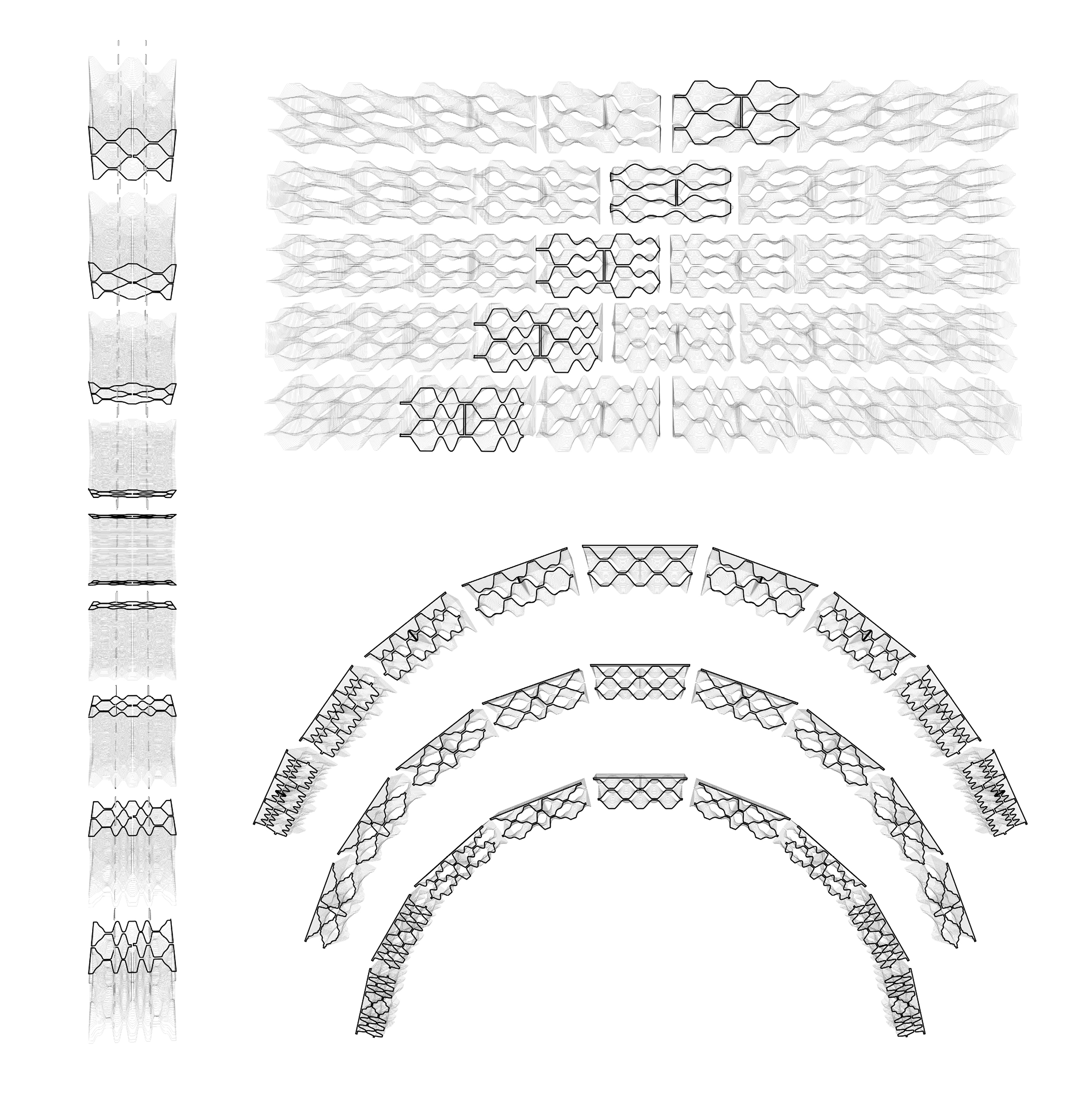

The concept of the project begins with an analysis of mathematic expressions defining various curves. From simple sine waves to the more complex Fourier curves, multiple matrices are created to visualize a series of units “built” from said curves. A parametric design program (Grasshopper)

The concept of the project begins with an analysis of mathematic expressions defining various curves. From simple sine waves to the more complex Fourier curves, multiple matrices are created to visualize a series of units “built” from said curves. A parametric design program (Grasshopper)

is used to provide a flexibility in changing the various factors that affect the geometry such as amplitude, frequency, period, and the limit. The curvatures act as a base to generate an undulating surface which then aggregates into a single unit. The undulation gives the unit a variation of perforation which allow for different lighting conditions and shadows dependent on the base curvature used.

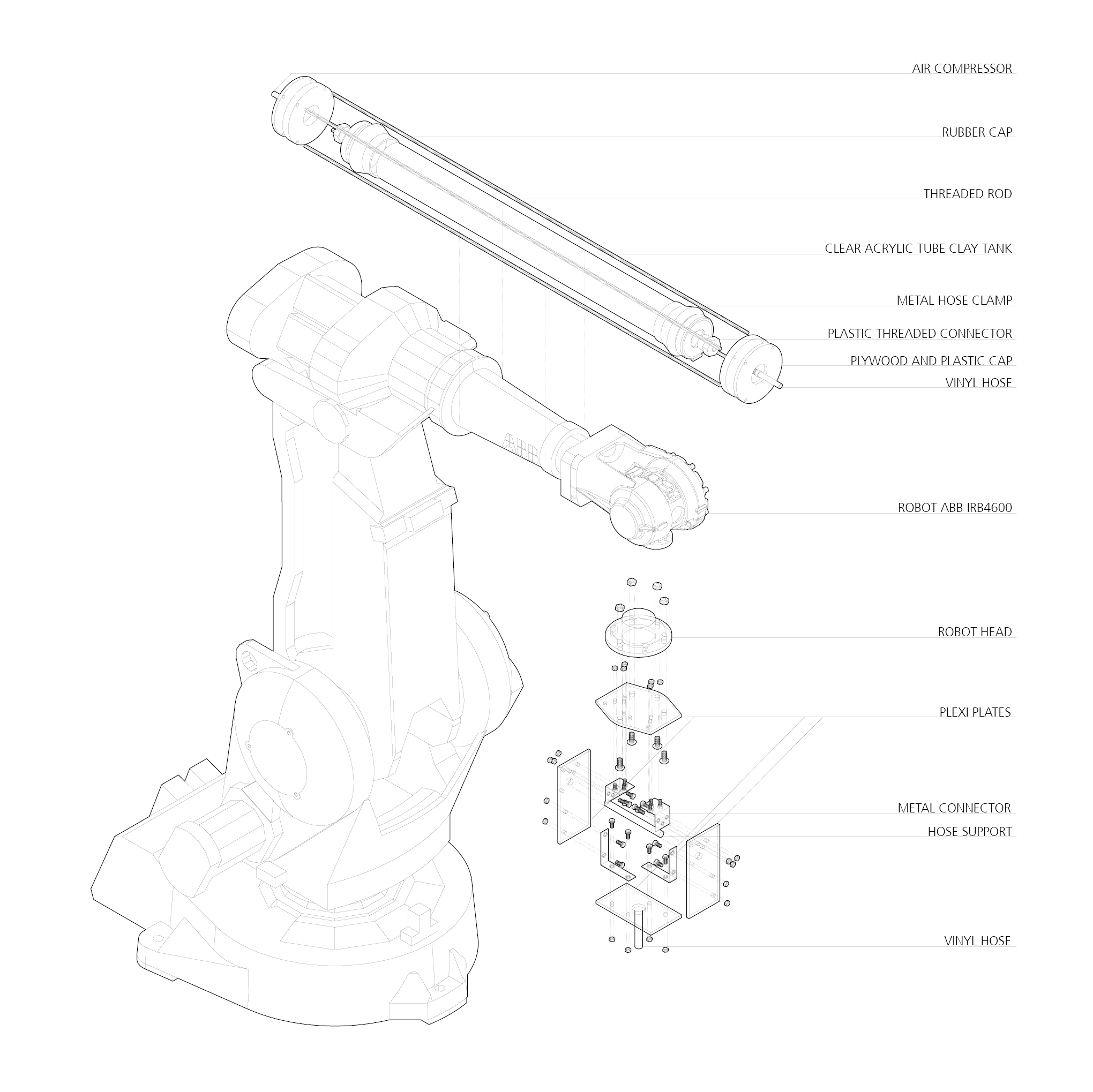

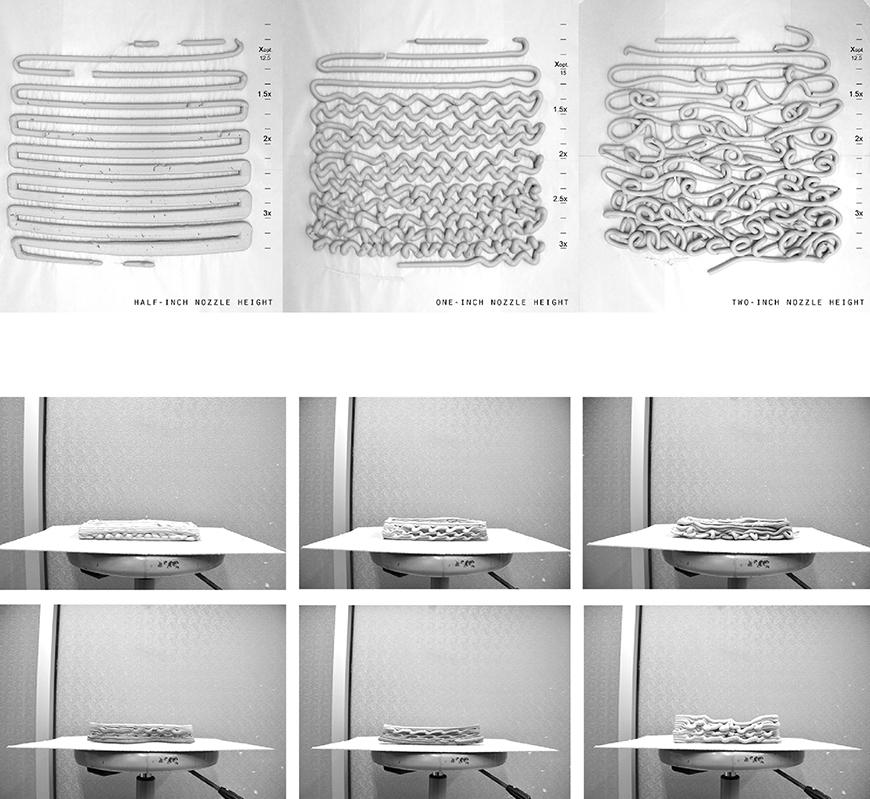

The final decision to use the pneumatic system is made based on constancy of the extrusion, predicted quality of the extrusion, and the ability to maintain the necessary force. Air pressure is produced and controlled through an air compressor. It is then directed through a hose to an acrylic tube containing the clay. Then a series of tests were designed to evaluate the multiple variables that exist within the process. The factors explored includes clay consistency, extrusion height, air pressure (psi), and robotic motion.

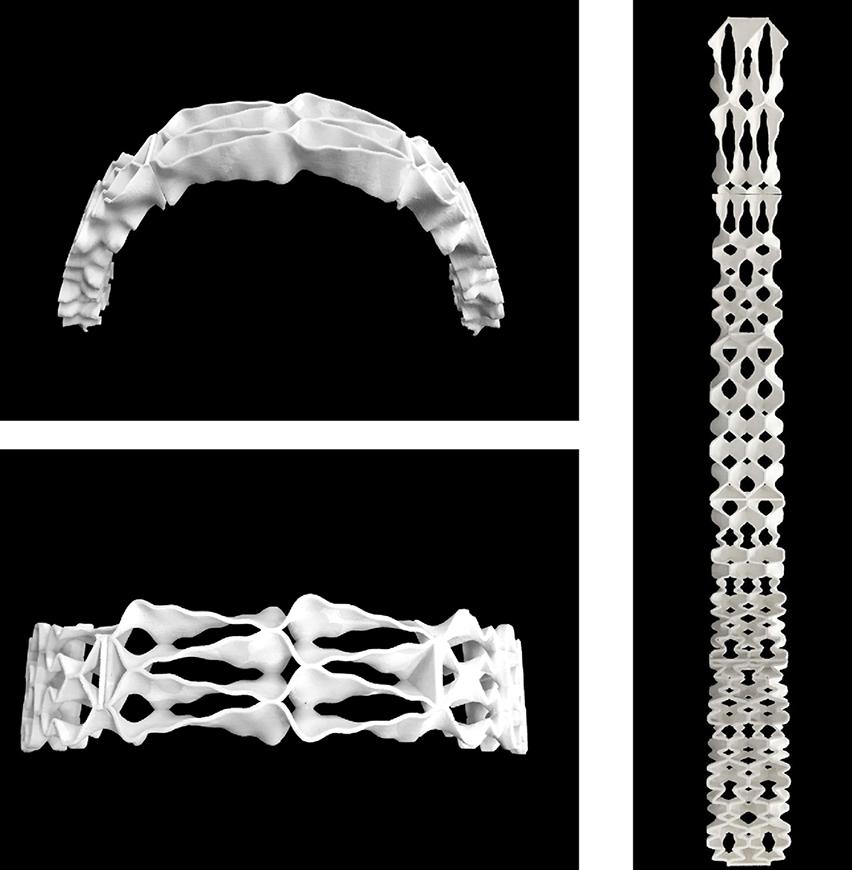

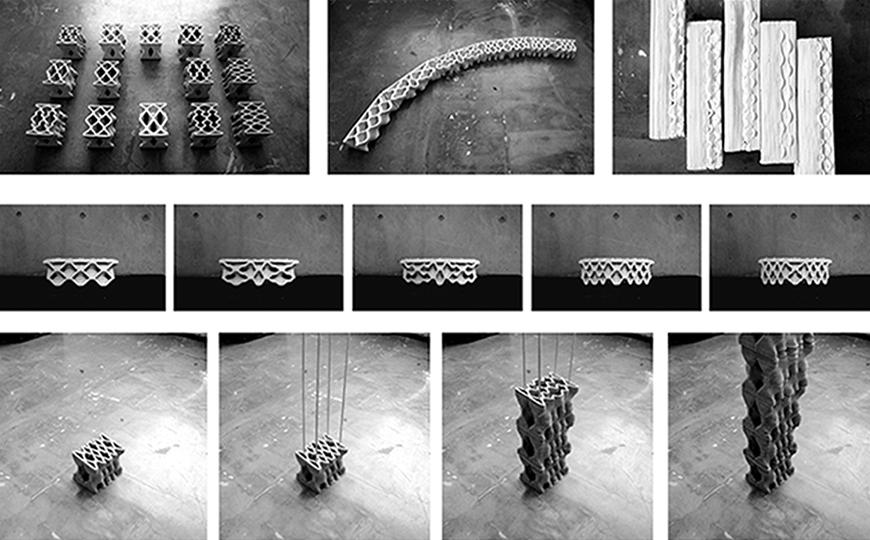

These units show potential in adapting to various structural forms. Due to the ease in changing the toolpath combined with a highly responsive material, the units can be modified according to their specific purposes. Through this project, we explored three types of structural typologies: the column,wall and arch. The modules' amptitudes are changed to best suit whichever system they are used in while simultaneously highlighting the certain innate qualities of the brick functioning structrally and viewed in certain orientations.

These units show potential in adapting to various structural forms. Due to the ease in changing the toolpath combined with a highly responsive material, the units can be modified according to their specific purposes. Through this project, we explored three types of structural typologies: the column,wall and arch. The modules' amptitudes are changed to best suit whichever system they are used in while simultaneously highlighting the certain innate qualities of the brick functioning structrally and viewed in certain orientations.